Agile transformation is an immensely popular undertaking for software companies that have come to value the speed of innovation in the competitive market of creative software solutions. The literature is vast, experts are numerous, and there are a multitude of approaches businesses can choose from to achieve market dominance by changing their ways of working and company culture. However, the jargon surrounding Agile methodologies is often vast and confusing, making the topic of agility overwhelming for newcomers.

When it comes to businesses that design and manufacture physical products, Agile with its manifesto can appear to be simply not applicable. However, we often forget that software companies were just as apprehensive over two decades ago. By embracing Agile principles, many software companies have since transformed their operations and cultures to better meet the needs of their markets. Although not trivial in the size of the undertaking, Agile Hardware Transformation is just as attainable.

Value Stream Identification in Agile Hardware Transformation

Value Stream Mapping (VSM) is a key element of lean product management, involving the mapping of steps in the flow of materials, processes, delivery, and information. This process includes identifying the resources needed to deliver a product or service. VSM often leads to the identification of inefficiencies, bottlenecks, and waste, which can then be optimized for better performance.

In this article, we will explore the process of Value Stream Identification, as proposed by the Scaled Agile Framework (SAFe®), a vital component of the VSM process. We will explore an enhanced approach of how to identify and analyse an organization’s current setup for delivering physical and cyber-physical products to the market, leveraging SAFe® Principle #10 – Organize Around Value – to enhance organizational structure and collaboration.

Preparations

Facilitating the identification of value streams is a complex task, especially when dealing with cyber-physical products, where frequently businesses encompass both the research & development then some aspects (if not all) the manufacturing operations. This task may involve multiple departments, partners, and suppliers, necessitating an understanding of the involvement of hundreds, if not thousands, of people. Therefore, careful preparation is essential to ensure the efficiency of this exercise.

- Select a Core Group

- Explain the Process

- Agree on Terminology

- Customer: A person placing a request for a service or an order for the finished product. This includes internal customers (e.g., manufacturing partners, suppliers) and external customers (e.g., B2C, B2B, B2G models).

- Consumer: Individuals or departments within the flow of value that consume the output of the work to execute their part.

- Users: Individuals who directly interact with the product and are the focus of the business.

- Software System: Software produced to support product development, enable products for users, or deliver direct value to users.

- Whole Solutions: Complete offerings, or ecosystems of products, delivered to users.

- Define the Scope of the Mapping Exercise It is important to define the scope of the business areas to be mapped, focusing on the differences in users or markets served rather than on departments or domains. Optimizing a department that serves multiple user types might create bottlenecks elsewhere and lead to misalignment in terminology, processes, and flows.

- Identify Initial Participants for Each Step Each step of the identification process will require various levels of information, so it is helpful to identify potential participants for each step at a high level. Keeping the workgroups small will be the key to efficiency, with core group always reviewing the outcomes for an opportunity to adjust the course.

The core group should include stakeholders with a broad knowledge base to assess the size of the task. These might be representatives from various departments, partners, and suppliers. It is crucial to balance the group’s size to include sufficient knowledge of the company’s setup without making the task overly lengthy.

The core group should fully understand the process and its purpose. They will be responsible for selecting team members from their areas who have the depth of knowledge required for the relevant steps of the VSM. They will also review and support the outcomes of each completed step to ensure accurate representation.

During the mapping exercise, participants will need to focus on specific areas, domains, and key aspects of their flow. It is beneficial to agree on the meanings of key phrases within the context of the organization. For example:

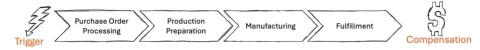

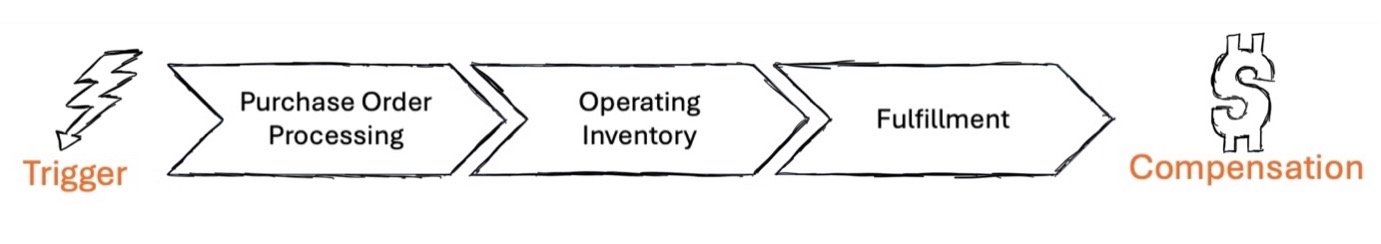

Identify Operational Value Streams

In this step, we focus on the individuals or businesses that pay for the products. We aim to understand the steps from the moment a customer requests a product or service to the point where the customer receives the product or service, and the business is compensated. Even a high-level understanding of this process is valuable for identifying differences between users and internal customers, both of whom deserve the same level of attention and respect. For example, let us consider a hypothetical company, ABC, that manufactures cars and sells them to B2C companies in different markets. The operational value stream might look like this:

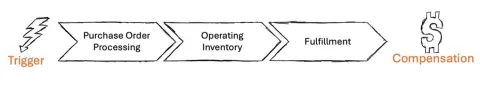

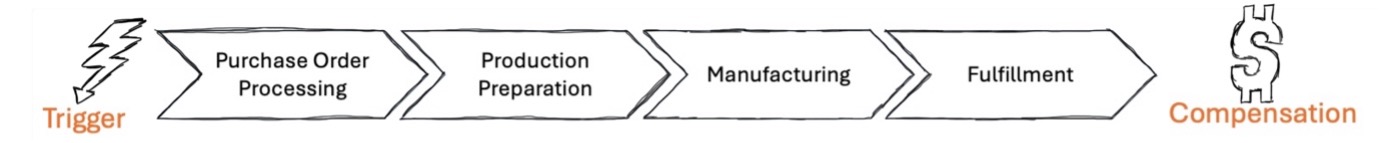

For businesses that manufacture products to order, the steps would differ slightly:

Identify Your Solutions

In the context of the ABC company, different car models represent separate income streams and solutions. Traditionally, each model or customization might have been a separate project. However, to organize around value, we should focus on the core architectures that form the baseline for every solution we build. For ABC, we might have three core architectures:

- small chassis for D model cars

- medium chassis for E model cars

- large chassis for SUV models

These core architectures remain unchanged for 6 to 10 years, with mid-cycle updates occurring every 3-4 years. By identifying the number of different architectures or platforms, we can determine the number of solutions.

Identify the Activities Necessary to Develop a Solution

In SAFe®, this step would be called Identify the people who develop and support the Solutions, but from our experience, doing so without missing out key collaborations is incredibly difficult in large and complex organizations with hundreds of people that deploy such Solutions to production. For this reason, we recommend taking an intermediate step and understanding the stages and the activities that take place during development.

For example, in ABC’s case, the process to manufacture a car might involve the following steps:

Each step involves various departments and activities. For instance, during the Definition of Requirements phase, mechanical designers and electronics engineers may create early mock-ups while suppliers and partners explore new parts. During the Development phase, tooling departments and production engineers might design the manufacturing lines for the new model. It is crucial not to overlook the integration of software products and other collaborations during these stages.

Identify the People Who Develop and Support the Solutions

Now that we understand the activities required, we need to identify the number of people involved. This includes mechanical, powertrain, electrical, and electronics engineers; exterior and interior designers; user experience and interface designers; production planning, tooling, and equipment teams; quality control and assurance teams; and IT and digital knowledge teams.

The knowledge sought here is not so much of the number of individuals as much as competences behind the activities. The expertise required to progress the design might be complex, and focusing on the number of people involved might mean that we will concentrate on numbers for each delivery stream, not the full set of competence required to make it efficient. Knowing the key competencies, then the number of people, and where they are located will help us organize for optimal collaboration and communication.

Identify the Delivery Value Streams that Develop the Solutions

In this step, we group the identified roles into Delivery Value Streams – groups of people that build one solution together. At first, we will focus purely on engineering staff to get an idea of rough numbers of all persons involved.

Next, we consider all the supporting roles such as procurement, compliance, marketing, and production support. These roles are crucial for making the product market-worthy, and collaboration with these teams is essential.

Once we know who the people with expertise in evolving products are, we should also get an idea of the difference between the Delivery Value Stream and Supporting Value Streams. These will be the people that our Delivery Value Stream must work with to successfully deliver whole solution design to manufacturing.

In our ABC car company, such an example of a Supporting Value Stream could be the group producing firmware that enables the digital technologies in our cars, or the team that makes cutting-edge cameras that are part of driver-assistance systems.

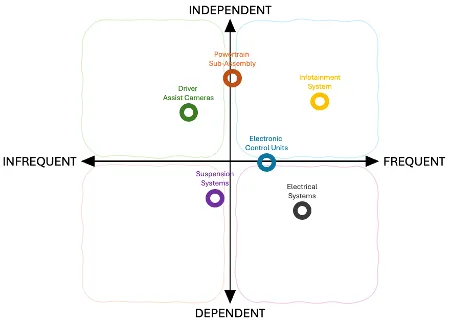

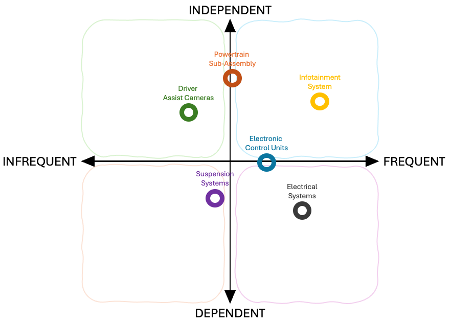

Create a Heatmap for Delivery Value Streams

Before progressing with the next step and organizing the value streams into Agile Release Trains (ARTs) or stable teams, we create a heatmap to identify the most independent value streams.

The objective here is to identify the Value Streams that are:

- Most self-contained, where teams work on a product or system that is largely independent from other elements of the solution.

- Developed infrequently, as in – it takes a long time to develop the technology.

This step helps us manage change effectively and choose the initial steps in the transformation process.

Realize Delivery Value Streams into Agile Release Trains

SAFe® recommends keeping teams as small as possible to enhance collaboration. Bearing in mind Dunbar’s number, we should visualize the Agile Release Trains or team of teams that will evolve our solutions, focusing on the required roles and numbers rather than the details of staffing.

Perform ART Validation Testing

Although optional in SAFe®, validation testing is crucial in designing a new organizational setup in a cyber-physical environment. Companies that deliver hardware products already employ Plan-Do-Check-Adjust (PDCA) cycles, building prototypes and mock-ups as part of their process. With the new setup of stable teams and ARTs, we need to consider how physical constraints impact feedback loops and the overall process. It is practical to consider three focus areas:

- Handling of the requirements and their dependencies between teams and ARTs

- The readiness of the organization for managing the upcoming change

- Distribution of work and the work in process limits

Some of the things we ought to think of are:

- How will our backlogs be shaped if the teams are no longer resources assigned to a new project?

- What is the rhythm of development for individual ARTs since in hardware, not everyone can or should start work on a new solution or its element at the same time?

- How will this new setup impact collaboration and communication?

- What is the slowest element of the new setup?

- How does the new setup impact our funding?

- How can we get more frequent feedback, and how can we use it to iterate the whole solution?

The Next Steps and Conclusion

Organizing Around Value in cyber-physical systems is a significant undertaking. The key to successful transformation lies in designing a robust change management plan. This includes:

- Mapping roles and responsibilities from current practices to the new setup.

- Designing a decision-making framework.

- Assessing organizational readiness.

- Developing a stakeholder engagement and communication plan.

- Creating tailored training programs.

- Establishing support systems such as coaching, mentoring, and help channels.

- Designing metrics and identifying key milestones.

- Creating a forum for regular feedback to foster continuous improvement.

Transitioning to an Agile framework in hardware manufacturing requires a deep understanding of processes and people. By focusing on value stream mapping and identification, organizations can streamline operations and enhance collaboration. Effective change management, strategic planning, robust communication, and continuous support are crucial for minimizing resistance and fostering a culture of continuous improvement. Empowering teams, celebrating successes, and learning from failures are key components of this journey. With strong leadership, commitment to organizational learning, and a willingness to adapt to new ways of working, organizations can achieve lasting change and unlock their full potential in delivering value to customers.

Acknowledgments

A big thank you to SAFe SPCs Averil Franklin Stewart and Lars Broden for sharing their experience and providing their perspectives that have contributed to this article.